Fines Agglomeration / Waste Reclamation

Faced with the need to agglomerate natural and anthropogenic materials in blast furnace and ferroalloy production? You will be helped by the experience of Direxa, the world leader in the design of large-scale briquetting factories. We will help to choose the best ways to prepare materials for briquetting, select the optimal binder and estimate the metallurgical properties of experimental briquettes. We will design a briquette factory based on our successful experience and on solutions that have led to the success of several projects around the world.

Our proven Solutions are based on innovations and the best available technologies that ensure the environmental viability of metallurgical sludge and dust recycling technologies.

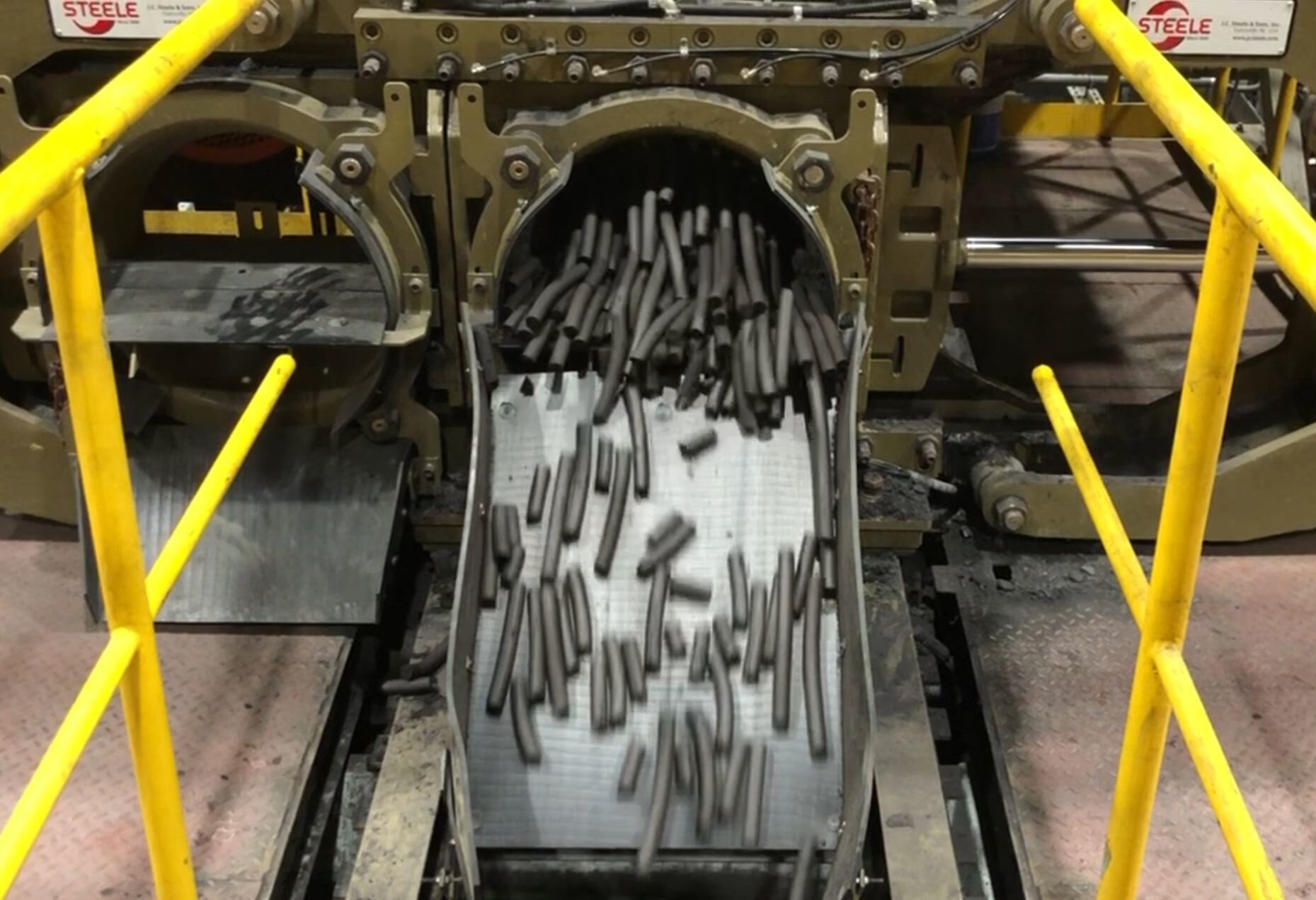

Fines agglomeration technology allows manufacturers to convert fines, dusts or sludges into quality feedstock with low binder content to increase material recovery and reduce the impact on the main production line.

This pelletizing technology is a sustainable alternative to fines wastes and by-products disposal. The pellets created are strong enough to be handled and transported so they can be efficiently re-introduced into the main production lines, effectively turning open-loop processes into closed-loop and more environmental-friendly processes.

The network of shared expertise within the JC Steele Group of Companies allows the customer to have one point of contact while designing a complete waste recovery or fines agglomeration solution; JC Steele & Sons brings 130 years of extrusion expertise, while Direxa designs and supplies the complete technological line.

In the Iron and Steel industry the typical by-products that can be recovered through this process are:

Blast furnace sludge, dust and fines

Iron ore pellet fines and concentrates

Metallized fines (DRI)

Mill scale

Baghouse dust

Ladle slag

Fly ash

In the Ferro Alloys industry the usual products that can be processed are ore, or dusts coming from dryer, kiln or furnace; and the most commonly recycled raw materials are:

Nickel laterite dusts

Ferro silicon dusts

Manganese ore fines or dusts

Chrome ore fines or dusts

Meet our expert for fines agglomeration: